1. Center feeding die

Mouth mold: φ30mm-φ2650mm

2.Side feeding die

Mouth mold: φ30mm-φ800mm

3. Planar stacking die

Mouth mold: φ150mm-φ800mm

Advantages: independent structure of the mold body, good uniformity and sealing.

Disadvantages: The process temperature of each layer of melt cannot be controlled independently, so when selecting the die head, it is necessary to consider that the process temperature of each layer of raw materials needs to be close.

The number of layers in the Blown Film Machine can be configured arbitrarily; the temperature of each layer can be controlled independently to accommodate process temperature variations, effectively preventing material degradation and facilitating easier processing, cleaning, and maintenance.

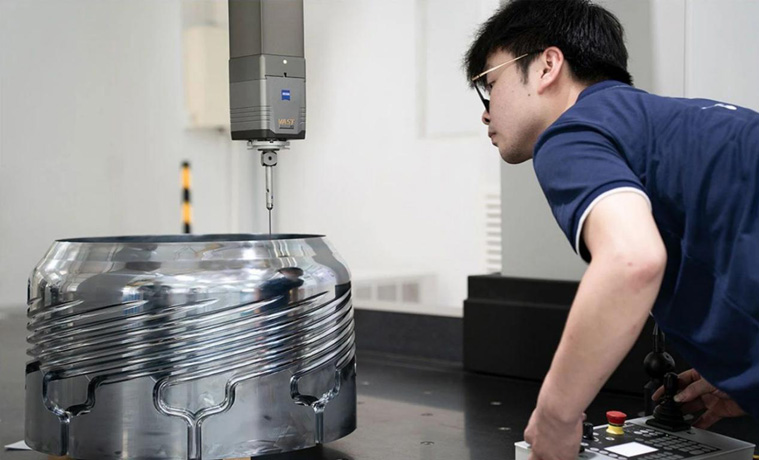

No matter what kind of die structure it is, the core key lies in the runner design. For the design of the spiral flow channel, Chaoxin's engineers used their rich experience and software analysis to calculate the pressure distribution, residence time and shear rate of the melt in the die, taking the parameters and output of the material as the initial conditions. And the most critical velocity distribution at the exit of the spiral flow channel.