Blown film machine hourglass-shaped film tubes mainly occur in two forms: regular hourglass shapes and irregular hourglass shapes.

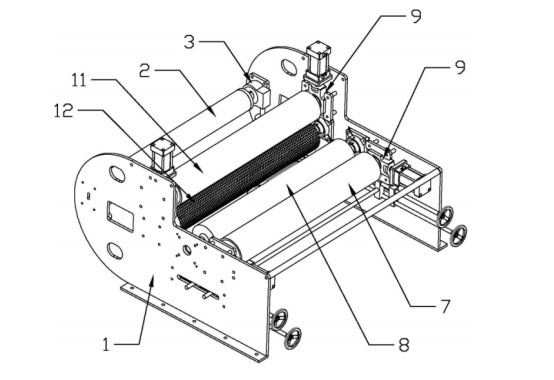

Regular hourglass-shaped film tubes are usually caused by insufficient clamping force of the traction rollers or by the traction roller speed being affected by mechanical transmission resistance changes. Specific causes include:

1. Insufficient Clamping Force of the Traction Rollers: When the clamping force of the traction rollers is insufficient, the film tube cannot maintain stable tension during traction, leading to periodic changes in the shape of the film tube.

2. Changes in Mechanical Transmission Resistance: Unstable factors in the mechanical transmission parts of the traction device cause the traction roller speed to fluctuate regularly, affecting the shape of the film tube.

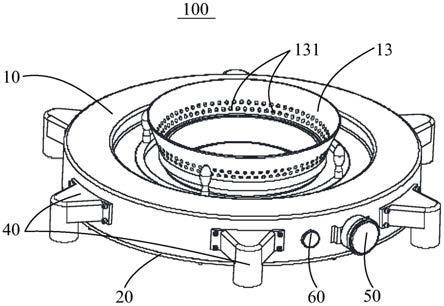

Irregular hourglass-shaped film tubes are usually caused by unstable traction speed and excessive air pressure from the cooling air ring. Specific causes include:

1. Unstable Traction Speed: When the traction speed fluctuates, the shape of the film tube cannot remain consistent, leading to irregular hourglass shapes.

2. Excessive Air Pressure from the Cooling Air Ring: Excessive air pressure from the cooling air ring can cause uneven cooling of the film tube surface, resulting in irregularly shaped film tubes.

Solutions for Hourglass-shaped Film Tubes

Increase the Clamping Force of the Traction Rollers: By appropriately increasing the clamping force of the traction rollers, ensure stable tension during the traction process, thus avoiding regular hourglass shapes.

Repair Mechanical Transmission Parts: Regularly repair the mechanical transmission parts of the traction device to ensure stable traction roller speed, reducing shape changes in the film tube caused by changes in mechanical transmission resistance.

Adjust Traction Speed: Ensure the stability of the traction speed, avoiding fluctuations, and ensure the consistency of the film tube shape.

Reduce Air Pressure from the Cooling Air Ring: Appropriately reduce the air pressure from the cooling air ring to ensure even cooling of the film tube surface, avoiding irregular shape changes.

ZHEJIANG CHAOXIN MACHINERY TECHNOLOGY CO., LTD.

Booth No:28B58

Time: January 27 - 30, 2026

Exhibition Hall Name:CROCUS EXPO International Exhibition Center

Add:Mezhdunarodnaya str. 16, 18, 20, Krasnogorsk, Moscow region, Russia

WEB: www.zjchaoxin.com