1. Improper head temperature control:

Blown film machine head temperature that is too high or too low can affect the plastic's flowability and traction.

Solution: Adjust the head temperature appropriately to keep it within the suitable range for the plastic material. Typically, the temperature is controlled within the upper and lower limits of the plastic's melting temperature to ensure good flowability and film formation.

2. Uniform outflow from the die:

Uniformity in the die gap is necessary for uniform film thickness and traction.

Solution: Adjust the die gap to be uniform. Also, adjust the temperature of the head connector to match the body temperature.

3.Contamination in the melted material:

Contaminants can clog the die and affect the uniformity and quality of the outflow.

Solution: Purify the raw material to ensure that it is free of contaminants. Regularly clean the head and screw to prevent the accumulation of carbon and contaminants.

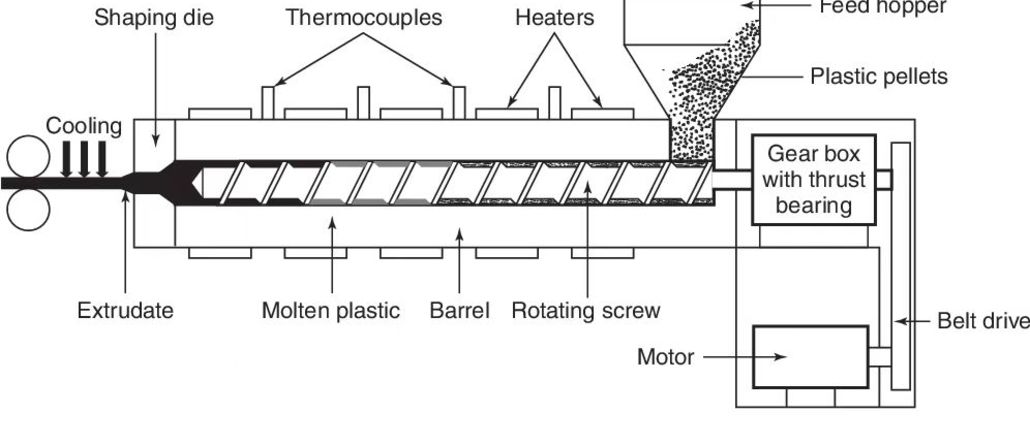

4.Improper control of extrusion process conditions:

Inappropriate process parameters (such as temperature, screw speed, and traction speed) can cause unstable flowability and outflow rate of the molten plastic.

Solution: Adjust the extrusion process conditions appropriately based on actual production conditions. Ensure that the extrusion temperature, screw speed, and traction speed are matched to achieve the best film formation effect.

5.Raw material issues:

Using low-quality or inappropriate raw materials can make film formation difficult.

Solution: Choose high-quality raw materials and adjust process parameters according to different plastic materials.

6. Cooling system issues:

Uniform or improper temperature control of cooling air can affect the shaping and traction of the film.

Solution: Check and adjust the cooling system to ensure that cooling air is evenly distributed and at an appropriate temperature.

7. Equipment issues:

Wear and malfunctions of equipment can cause unstable film formation.

Solution: Regularly maintain equipment and replace worn parts to ensure normal operation.

8. Inappropriate mold design:

Inappropriate mold structure, outlet position, etc. can affect the traction effect and forming quality of the film.

Solution: Optimize mold design to ensure that outlet layout is reasonable, reducing dead corners and resistance, and improving plastic fluidity. At the same time, adjust mold parameters according to actual production needs to achieve the best forming effect.

9. Environmental temperature and humidity issues:

High temperature or humidity in the production environment can affect the extrusion process and cause unstable film traction.

Solution: Control the temperature and humidity in the production workshop to maintain a constant temperature and humidity within the suitable range. Take effective ventilation and cooling measures, and strictly monitor changes in environmental conditions.

10. Operator technical level varies:

Operators with varying levels of knowledge about extrusion equipment operation may set the process parameters incorrectly or make mistakes in operation.

Solution: Strengthen operator training and skill improvement plans to ensure that each operator is proficient in the use of equipment and related knowledge, and establish a complete record and feedback mechanism.

11. Poor storage conditions for plastic materials:

Raw materials exposed to humidity, direct sunlight, etc. for a long time are prone to moisture, mold, and aging problems.

Solution: Optimize the storage method of raw materials, control the storage environment, avoid moisture and mold of raw materials, and choose fresh and high-quality raw materials for production.

12. Lack of monitoring of equipment operating status:

There is no comprehensive and systematic monitoring of equipment operating status and data analysis means.

Solution: Introduce advanced intelligent monitoring devices and establish a reliable data analysis system to promptly detect and handle abnormal situations and provide early warning of fault risks.

13. Inadequate cleaning and maintenance of production lines:

Cleaning and maintenance of Blown Film Machine have not been given enough attention.

Solution: Strengthen the management of daily cleaning and maintenance of production lines, regularly check whether each component is clean and free of accumulated contaminants, and carry out necessary replacement and repair.