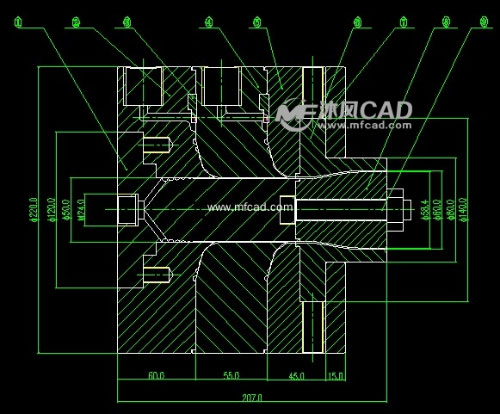

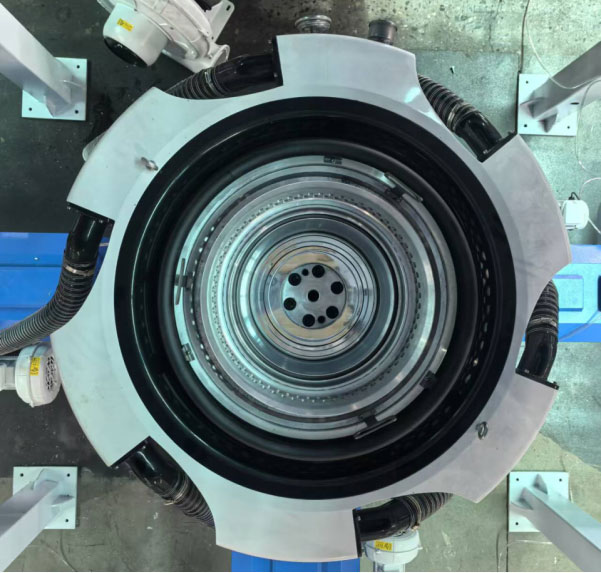

As an important part of the blown film machine, the ABA die plays a crucial role in plastic film production. The ABA die features a double-extruder design, and the die head has a three-layer structure. Among them, the inner and outer layers are supplied and extruded by one screw, known as the AA layer; the middle layer, i.e., the B layer, is supplied and extruded by another screw.

This design has significant advantages. Firstly, it is mainly used to improve the tensile strength of the film. For example, in actual production, by reasonably adjusting the parameters of the ABA die, both the transverse and longitudinal tensile strengths of the film can reach a relatively good level. When the blow-up ratio (BUR) and the draw-down ratio (DDR) reach a certain proportion, the tensile strength of the film can be effectively enhanced. Generally speaking, to reduce the DDR, the die gap can be reduced, and decreasing the BUR may lead to a larger DDR. If the film bubble is unstable, it may be due to an overly large BUR.

Secondly, the ABA die can reduce costs. A high percentage (up to 50% to 70%) of CaCO3 compound or recycled material can be used in the middle B layer, while the inner and outer layers (AA) can be filled with pure materials to maintain good surface quality of the film. This significantly reduces the use of original raw materials, thereby lowering production costs. Taking the ABA three-layer machine as an example, it has been widely used in the production of plastic bags and ordinary packaging bags as early as 2005, and has shown significant growth in the markets of Middle Eastern and European countries. Especially in the market where the price of HDPE raw materials has risen sharply, the ABA die has great advantages in reducing production costs, improving product quality and competitiveness. Especially for 15 - 30 micron HDPE, the original materials are mainly applied to the AA (inner and outer) layers, which account for a very small proportion of the film composition, with a ratio of approximately 1:6:1 (inner layer: middle layer: outer layer).

The ABA die extrudes three different plastic melts through two extruders in a three-layer co-extrusion manner. This unique method enables different plastic materials to converge at the die head and be simultaneously blown to form a three-layer plastic film. During this process, the materials for each layer can be selected and adjusted according to specific requirements to meet different performance requirements. For example, the outer layer can be selected with materials having good weather resistance and printability, the middle layer can use materials containing a high percentage of recycled materials or calcium carbonate compounds to reduce costs, and the inner layer can be selected with materials having good compatibility when in contact with the packaged objects.

In the double-screw extruder of the ABA die, the two screws are meshed with each other, forming a series of C-shaped chambers. As the screws rotate, these C-shaped chambers move axially along the meshing part, so that the material is continuously pushed forward by the threads. This forced conveying method has a powerful conveying capacity, which can ensure the stable flow of the material during the extrusion process. According to the data in the search materials, the speed VL of the C-shaped chamber moving axially along the screw = t・n, where t is the screw lead and n is the screw rotational speed. The theoretical extrusion volume Q of the counter-rotating fully meshing twin-screw extruder = 2n・V, where V is the volume of a single C-shaped chamber. However, in fact, due to the clearance between the screw and the inner wall of the barrel, there will be a leakage flow phenomenon, so that the output cannot reach the theoretical output. In addition, the relative speed VrA at the meshing point of the counter-rotating fully meshing twin-screw = 2π・n (Rb - Rs), where VrA is the relative speed between the side clearances of the two screws at point A, Rb is the outer radius of the screw, and Rs is the inner radius of the screw. This relative speed makes the counter-rotating fully meshing twin-screw have good self-cleaning ability, which can reduce the residue of the material during the extrusion process and improve production efficiency and product quality.

The ABA die adopts the design of two extruders, an ABA type distributor and a three-layer die head, which greatly improves the tensile strength and performance of the film. This design enables the film to better withstand external forces during the production process and has higher strength and durability.

There are various alternative designs for the die head, including stationary and rotating die heads, as well as general and fully automatic winding methods. These alternative designs can be selected according to different production requirements, improving the flexibility and adaptability of production.

For example, when producing films requiring high precision and high quality, a rotating die head can be selected to ensure the thickness uniformity and surface quality of the film. And in some large-scale production occasions, the fully automatic winding method can improve production efficiency and reduce the cost and error of manual operation.

According to the different order quantities and product requirements, different screw and die head configurations can be selected. If the order quantity of vest bags is large and stable, a double-screw ABA double-blown film machine die head can be recommended. This die head has the advantages of high output, good tension and good film blowing brightness.

The double-screw design can meet the demand for a large extrusion volume. For cases where customers have high requirements for the tensile strength of bags, such as express delivery film, food packaging film, medical packaging film, etc., double-screw and multi-screw co-extrusion are ideal choices.

At the same time, for some cases where industrial bags and market bags need to be made, a single-die single-screw is more convenient for replacing high and low pressure die heads to adapt to different production requirements.

In addition, a single screw also has a double-layer mold configuration, which is mainly used by some customers to blow garbage bags and vest bags, which can improve the tensile strength of the double-layer die head on the mold.

In short, the ABA die can provide a variety of screw and die head configuration schemes according to different order quantities and product requirements to meet the needs of different customers.

The ABA die is mainly used to produce three-layer plastic films, such as food packaging bags, drug packaging bags, composite packaging films, protective films, express delivery bag films, etc., and plays an important role in many fields.

In the field of food packaging bags, the film produced by the ABA die has good barrier properties, which can effectively prevent the invasion of oxygen, moisture and odors, and maintain the freshness and taste of food. For example, according to the data in the search materials, one of the main uses and applications of the ABA blown film machine is to produce fresh-keeping bags. The outer layer uses pure materials to cover the film surface, and the middle layer can use 40% - 70% of CaCO3 compound or recycled materials, which reduces costs while ensuring the film quality. In addition, the food packaging bags produced by the ABA die also have good printability, which can meet the requirements of food packaging for appearance design.

In the field of drug packaging bags, the requirements for the film are more stringent, and it needs to have good moisture-proof, oxygen-proof, and light-proof properties to ensure the quality and safety of drugs. The three-layer structure film produced by the ABA die can meet these requirements and provide reliable packaging for drugs. At the same time, the ABA die can also adjust the thickness, strength and barrier properties of the film according to the characteristics and packaging requirements of drugs to ensure that the drugs are not damaged during transportation and storage.

Composite packaging film is another important application field. The ABA die can produce composite packaging films with various properties, such as high strength, high barrier property, high temperature resistance, and low temperature resistance. These composite packaging films are widely used in the packaging of electronic products, cosmetics, daily necessities and other industries, providing good protection and display effects for products.

Protective film is also one of the applications of the ABA die. The protective film produced by the ABA die has good adhesiveness, wear resistance and weather resistance, and can be used to protect the screens and casings of electronic products such as mobile phones, computers, tablets, as well as the surfaces of automobiles, furniture and other items.

Express delivery bag film is a rapidly developing field in recent years. With the vigorous development of the e-commerce industry, the demand for express delivery bags is constantly increasing. The express delivery bag film produced by the ABA die has high strength, puncture resistance and waterproof properties, which can effectively protect the safety of express items during transportation. At the same time, the ABA die can also adjust the thickness and size of the film according to the different specifications and requirements of express delivery bags to improve production efficiency and reduce costs.

In short, the ABA die has broad application prospects in the fields of food packaging bags, drug packaging bags, composite packaging films, protective films, express delivery bag films, etc., providing strong support for the development of various industries.