During the production process of the film blowing machine, film staining at the film mouth is a common problem, which will not only affect product quality, but may also lead to a decrease in production efficiency. So, what exactly causes the film mouth to be stained with film, and how to solve it?

1. The raw material model is wrong. If polyethylene particles that are not blown film grade are used, or if they do not contain an opening agent or the content of the opening agent is low, film sticking will easily occur.

2. The temperature of the molten raw materials is too high. Too high a temperature will make the raw materials too fluid, increasing the possibility of film sticking.

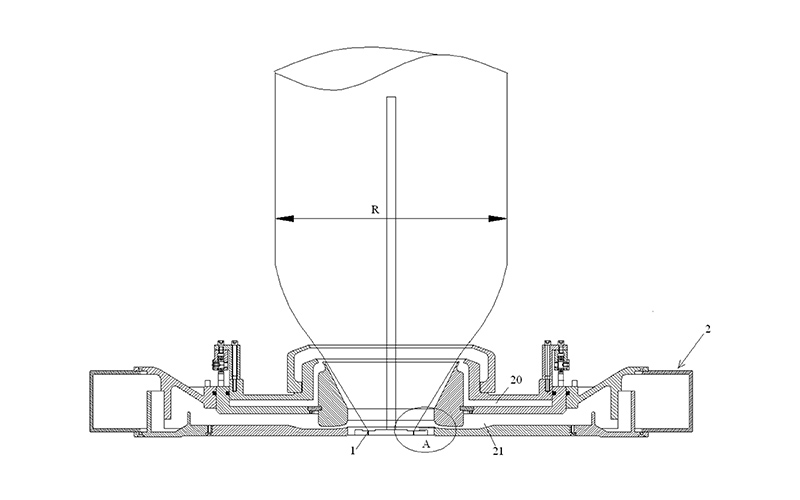

3. The inflation ratio is too large. If the blow-up ratio is too large, the opening of the film will deteriorate, causing film sticking.

4. The cooling speed is too slow. If the film is not cooled enough, it will easily stick to each other under the pressure of the traction roller, causing film sticking.

5. The traction speed is too fast. Too fast traction speed may also cause the film mouth to be stained with film.

1. Select the appropriate raw material, make sure it is blown film grade polyethylene particles, and add an appropriate amount of opening agent.

2. Reduce the extrusion temperature and raw material temperature to reduce the fluidity of the raw material.

3. Appropriately reduce the blowing ratio to make the film have better opening.

4. Increase the air volume and cooling speed to ensure that the film can be fully cooled.

5. Reasonably adjust the traction speed to avoid film staining caused by too fast traction speed.

ZHEJIANG CHAOXIN MACHINERY TECHNOLOGY CO..LTD

Booth No: 1K11

Time: 2025. 4. 15 - 18

Add: Shenzhen World Exhibition & Convention Center (Bao'an), PR China