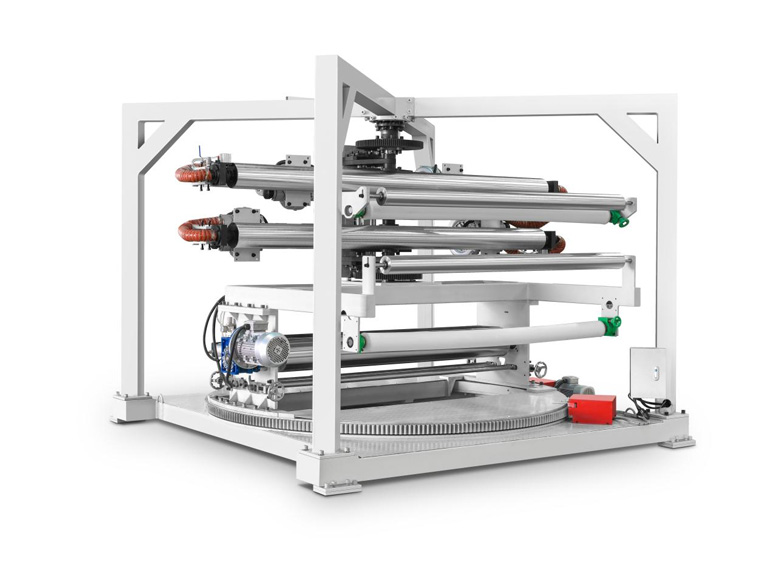

The upper spiral internal cooling system of the blown film machine involves a complex process of bubble formation and cooling control. In this system, a specific temperature and speed of cooling air or liquid (usually a cooling medium below ambient temperature) are introduced into the interior of the bubble, rapidly lowering the internal temperature. This rapid cooling in the early stages of film formation helps maintain the bubble at a lower temperature, facilitating faster solidification and congealing of the plastic material.

This system requires precise heating and cooling balance. Through the heating system of the film blowing machine, it ensures the formation of a stable bubble once the plastic material enters the machine. The upper spiral internal cooling system, by regulating the internal cooling speed, maintains an appropriate balance of heating and cooling to ensure film stability and uniformity.

The upper spiral internal cooling system significantly reduces the thermal shrinkage of plastic film through internal cooling. This technology reduces the deformation caused by film shrinkage, enhancing product stability and controllability.

The internal cooling system accelerates the solidification speed of the film, resulting in faster processing speeds and higher production efficiency. Additionally, rapid cooling contributes to improved film uniformity and quality.

Operators can precisely control the thickness and quality of the film through the internal cooling system. This system allows adjustments to cooling speed and temperature for more precise film production, enhancing production line stability and controllability.

Compared to traditional external cooling methods, the internal cooling system more efficiently utilizes energy, reducing energy consumption during production. Additionally, faster production speeds and reduced scrap contribute to environmental conservation, making production more environmentally friendly.

The application of the upper spiral internal cooling system improves control in the production process, reducing production defects caused by temperature variations or uneven cooling, ensuring consistent product quality and stability.

The upper spiral internal cooling system improves film uniformity and quality, reducing defects and deformities during production. This improved temperature control helps enhance product quality and stability, improving control in the production process.

In addition to enhancing product quality, the upper spiral internal cooling system plays a vital role in sustainability. Its fast cooling characteristic reduces energy consumption and waste production, contributing to less environmental impact, making production more environmentally sustainable.

As the technology of the upper spiral internal cooling system continues to innovate and improve, it is expected to remain pivotal in the plastic film production industry. More manufacturers may adopt this technology to enhance product quality, reduce production costs, and better align with environmentally sustainable production principles.

The upper spiral internal cooling system, as a crucial innovation in film blowing machine technology, profoundly influences the quality and efficiency of plastic film production. Its advantages lie in improving product quality, production efficiency, and transforming production processes towards sustainability and environmental-friendliness. With ongoing technological advancements, we anticipate this technology will continue to evolve, bringing further innovation and progress to the industry.