A prominent packaging manufacturer in West Africa, specializing in drinking water pouch production, discovered Chaoxin Co-Extrusion Blown Film Making Machine through a Google search and initiated contact with our sales manager, Nelson. With decades of industry experience, the client’s factory had established strong regional recognition but faced critical challenges due to outdated equipment and low automation levels. Their existing machinery could not meet growing market demands, and they urgently sought advanced solutions to modernize production while adding printing capabilities to their workflow.

Achievements:

1. Production capacity increased by 220%, labor costs reduced by 65%.

2. Added high-definition printing capabilities to promote business upgrades.

3. Highly recognized by customers, plans for secondary cooperation and expansion.

The client initially believed that purchasing multiple small-scale Co-Extrusion

On Blown Film Making Machines was the only way to boost output for their compact product specifications. Their technical understanding lagged behind current industry standards, and they were unaware of how integrated, automated systems could revolutionize their operations. Key hurdles included:

1. High labor costs and inefficiencies from manual processes.

2. Limited capacity to expand into printed packaging.

3. Overreliance on fragmented, low-output equipment.

After a thorough analysis of the client’s workflow, Nelson recommended our”low-pressure ABC1600 multilayer Co-Extrusion Blown Film Making Machine”– a game-changing solution featuring:

Advanced thermal cutting and slitting blades enabling simultaneous production of 6–8 film rolls.

1. Fully automated controls reducing manual intervention by 70%.

2. Modular design supporting seamless integration of printing units.

3. Energy-efficient operation ideal for small-to-medium specifications.

Nelson emphasized how this single system could replace multiple legacy machines while cutting operational costs, space requirements, and staffing needs. A virtual demo and ROI analysis convinced the client to adopt this forward-looking approach.

Results: Achieving 220% Growth and 65% Labor Cost Reduction

Within one months of installation:

1. Productivity surged by 220% with continuous 24/7 operation.

2. Labor costs dropped by 65% through full automation.

3. New high-definition printing capabilities unlocked premium market opportunities.

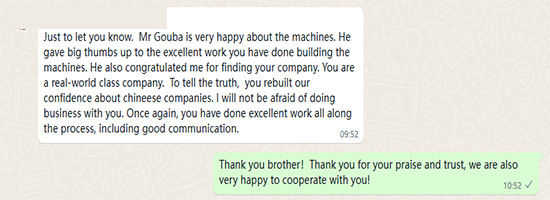

The client praised Chaoxin"world-class engineering" in a Whatapp post, noting:

"Chaoxin didn’t just sell us a machine – they transformed our business model. We’re now planning a second production line and will exclusively partner with them for our expansion."

1. Technical Expertise: Customized solutions bridging knowledge gaps.

2. Future-Ready Design: Scalable systems accommodating growth.

3. Global Support: Onsite training and 365-day maintenance coverage.

Let Chaoxin Machinery engineer your production evolution. Contact Nelson at +86 17816813735 to start your upgrade journey.