Main motorSiemens(Germany) ,Brook(UK) ,GE(USA)

Suitable materialsHDPE/LDPE/LLDPE

Screw L/D32:1

InverterSchneider(French), ABB(Switzerland)

Temperature-controlled meterOmron

Air ringDouble vent air ring

Output120-220kg/h

Product Specifications

| Model | CX-55-1100 | CX-60-1300 | CX-65-1600 | |

| Suitable materials | HDPE,LDPE,LLDPE | HDPE,LDPE,LLDPE | HDPE,LDPE,LLDPE | |

| Film width | 500-1000mm | 600-1200mm | 1000-1500mm | |

| Film thickness | 0.01-0.15mm | 0.01-0.15mm | 0.01-0.15mm | |

| Output | HDPE | 120kg/h | 150kg/h | 190kg/h |

| LDPE | 150kg/h | 180kg/h | 220kg/h | |

| Extrusion unit | ||||

| Screw diameter | Φ55 | Φ60 | Φ65 | |

| Screw L/D | 30:1 | 32:1 High speed screw | 30:1 | 32:1 High speed screw | 30:1 | 32:1 High speed screw | |

| Screw material | Double alloy material | Double alloy material | Double alloy material | |

| Barrel material | Double alloy material | Double alloy material | Double alloy material | |

| Barrel cooling fan | 370w*3 | 370w*3 | 370w*4 | |

| Main motor | 22kw | 30kw | 37kw | |

| Barrel temperature control | Zone 4 | Zone 4 | Zone 4 | |

| Average power consume | 25kw | 35kw | 60kw | |

| Die unit | ||||

| Die head | Φ220mm | Φ250mm | Φ320mm | |

| Temperature control | ZONE 7 | ZONE 8 | ZONE 8 | |

| Air ring | Double vent air ring | Double vent air ring | Double vent air ring | |

| Air blower | 7.5kw | 11kw | 11kw | |

| Take-up unit | ||||

| Roller width | 1100mm | 1300mm | 1600mm | |

| Effictive width | 1000mm | 1200mm | 1500mm | |

| Take-up speed | 10-120m/min | 10-120m/min | 10-120m/min | |

| Take-up motor | 1.5kw | 1.5kw | 2.2kw | |

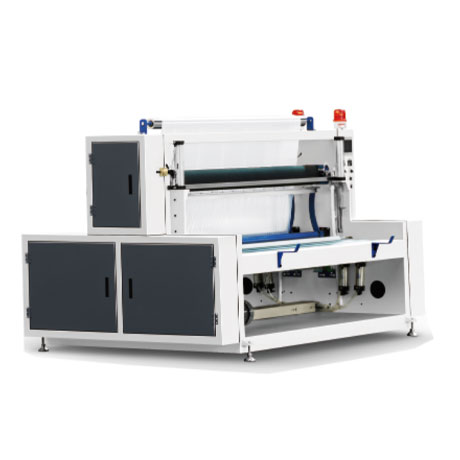

| Winding type | PLC automatic winding with EPC system | PLC automatic winding with EPC system | PLC automatic winding with EPC system | |

| Winding speed | 10-120m/min | 10-120m/min | 10-120m/min | |

| Voltage | 380V,50HZ,3PHASE | 380V,50HZ,3PHASE | 380V,50HZ,3PHASE | |

| Machine weight | 3.5T | 4.5T | 5T | |

| Machine size (L*W*H) | 6.5*3.2*6.8m | 7*3.5*6.8m | 7*4*7.5m | |

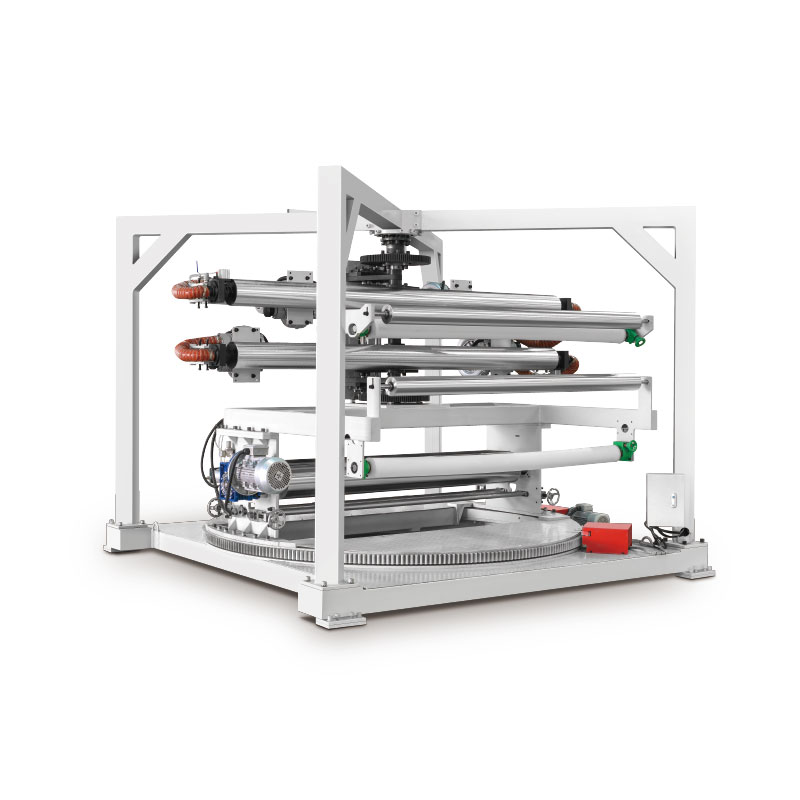

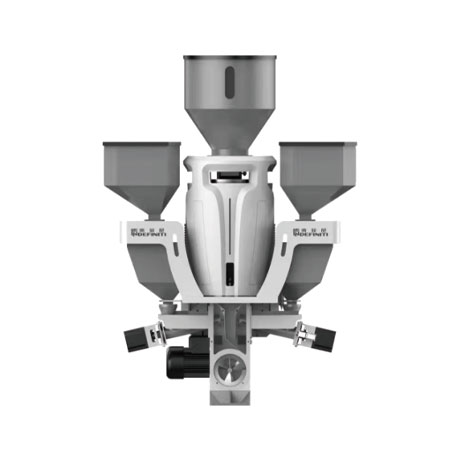

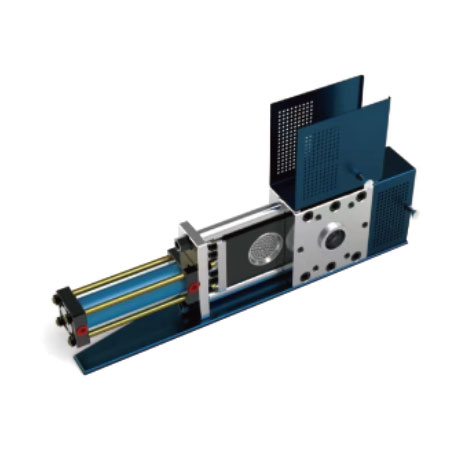

Optimized screw raises the extrusion volume and using lifespan. Higher anti-corrupt and anti-grind ability.

The motor operates with frequency conversion, which shows its advantages in terms of energy saving.

The up-traction determines the Traction stability, plastic film flatness and embossing effect.

The thick frame makes the machine more durable and reliable.

External circulation oil cooling system and hard tooth ensures the high working speed and lifespan of the gear joint.

Advanced heating is much better in terms of life, heating speed and heat preservation effect than stainless steel heating.

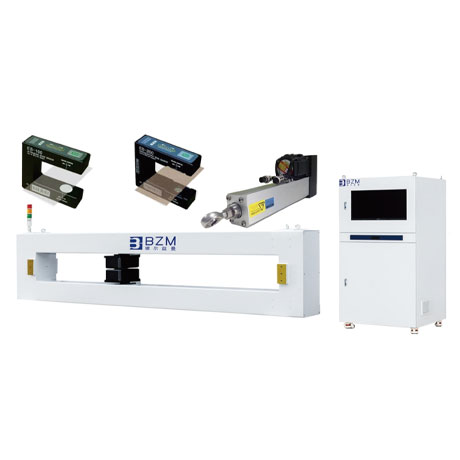

The structurally optimized high-speed air ring reduces the wind resistance and make the change of wind volume gentle.

Chaoxin creates a precedent of guarantee period in this industry, which enables clients to get trully hassle-free products & sevice.

5S management standards and high-end machining center equip Chaoxin with precision production capabilities and ensure product standards and quality.

ZHEJIANG CHAOXIN MACHINERY TECHNOLOGY CO..LTD

Booth No: GH189

Time: March 24-28, 2025

Add: SÃO PAULO EXPO – EXHIBITION & CONVENTION CENTER