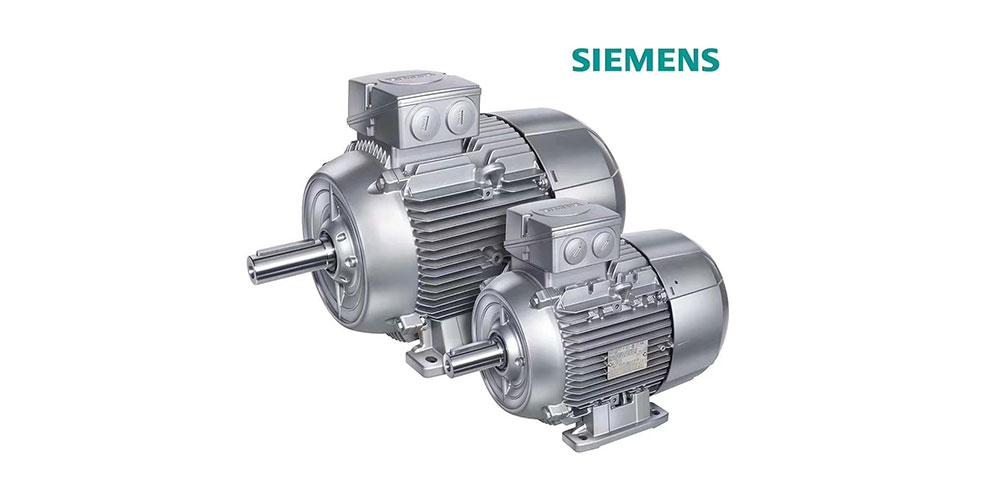

Main motorSiemens(Germany) ,Brook(UK) ,GE(USA)

Suitable materialsLDPE/LLDPE/PBAT+PLA

Screw L/D30:1

InverterSchneider(French), ABB(Switzerland)

Temperature-controlled meterOmron

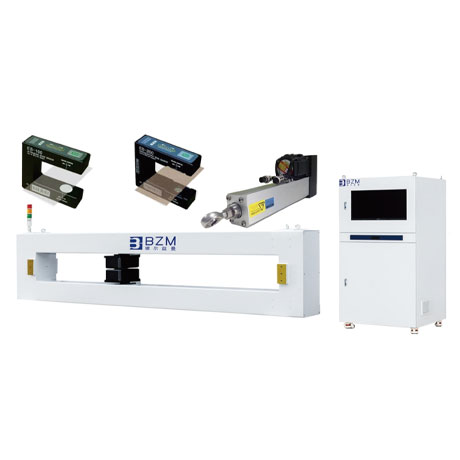

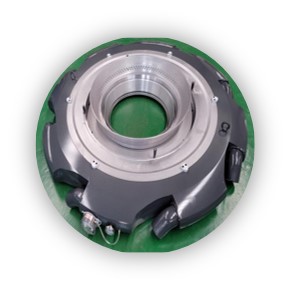

Air ringDouble vent air ring/Three vent air ring

Output80-160kg/h

Product Specifications

| MODEL | CX-1300 | CX-1700 | CX-2200 |

| Suitable materials | LDPE, LLDPE, PBAT | LDPE, LLDPE, PBAT | LDPE, LLDPE, PBAT |

| Film width | 800-1200mm | 1000-1600mm | 1200-2100mm |

| Film thickness | 0.006-0.03mm | 0.006-0.03mm | 0.006-0.03mm |

| Max.extrusion output | 100kg/150kg | 120kg/180kg | 150kg/200kg |

| Screw diameter | 65mm | 75mm | 85mm |

| Screw L/D | 32:1/30:1 | 32:1/30:1 | 32:1/30:1 |

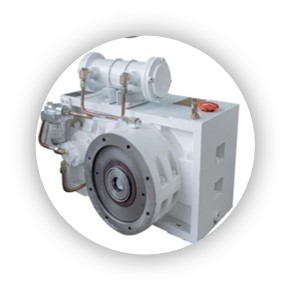

| Gearbox | 180 | 200 | 225 |

| Main motor | 30kw | 37kw | 45kw |

| Air blower | 5.5kw | 7.5kw | 11kw |

| Average power consumption | 30kw | 40kw | 50kw |

| Die diameter | 250mm | 350mm | 500mm |

| Traction roller width | 1300mm | 1700mm | 2200mm |

| Dimension/Weight | 6*3.5*6.5m/4T | 6*4*7.5m/5.5T | 7*4.5*9.5m/7.5T |

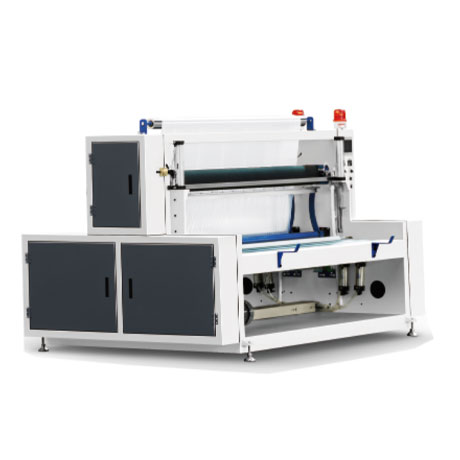

As the pace of agricultural modernization continues to accelerate, we are proud to introduce an excellent agricultural film blowing machine to provide advanced and efficient solutions for agricultural production and help the agricultural industry achieve greater income.

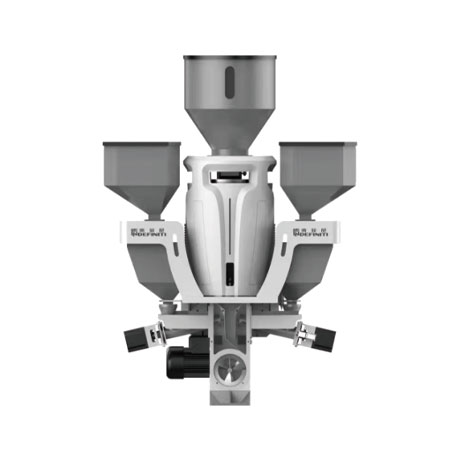

Agricultural film blowing machine adopts double alloy screw, equipped with double tuyere and three air vents, and realizes efficient processing of various materials (such as PLA+PBAT, LDPE, LLDPE) through precise extrusion technology. Excellent performance in film production not only increases the yield, but also ensures the flatness and quality of the film.

The equipment is equipped with a temperature control system of 5 zones, which realizes multi-zone independent temperature regulation and ADAPTS to the process requirements of different materials. The excellent performance of the system increases the flexibility and control of production, ensuring stability and consistency in the film production process.

The motor and control system of top brands such as Siemens of Germany, Bruker of Britain and GE of the United States are used to ensure the high stability and reliability of the equipment. The inverter was selected by Schneider of France and ABB of Switzerland, while the temperature control system relied on the Omron brand to provide excellent electrical performance for the entire system.

The average power consumption is between 40 kW and 60 kW, enabling efficient use of electrical energy. At the same time, the adjustable winding speed of the equipment ranges from 10 m/min to 120 m/min to meet different production needs and ensure the flexibility of the production process.

The overall size is 7.5 meters * 4.5 meters * 9.5 meters, and the weight is between 3.5 tons and 5.5 tons, which not only ensures the stability and reliability of the equipment, but also provides more convenient conditions for installation and operation. The strong structure of the machine ensures that excellent performance is always maintained at work.

This agricultural film blowing machine is a sign of the upgrading of agricultural science and technology, which not only improves the yield and film quality, but also infuses efficient and advanced elements into agricultural production. Choose our equipment, you will usher in a new era of technological leap in agricultural production and harvest. Welcome to contact us to create a better future for the agricultural industry!

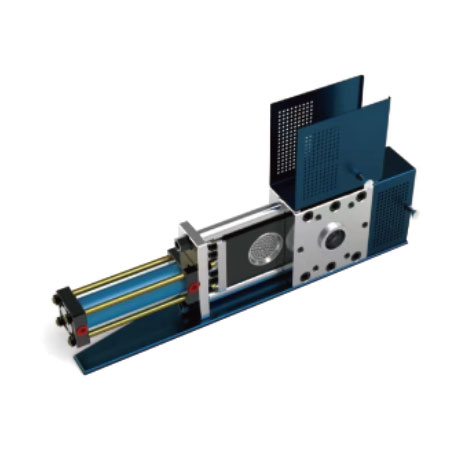

Optimized screw raises the extrusion volume and using lifespan. Higher anti-corrupt and anti-grind ability.

The motor operates with frequency conversion, which shows its advantages in terms of energy saving.

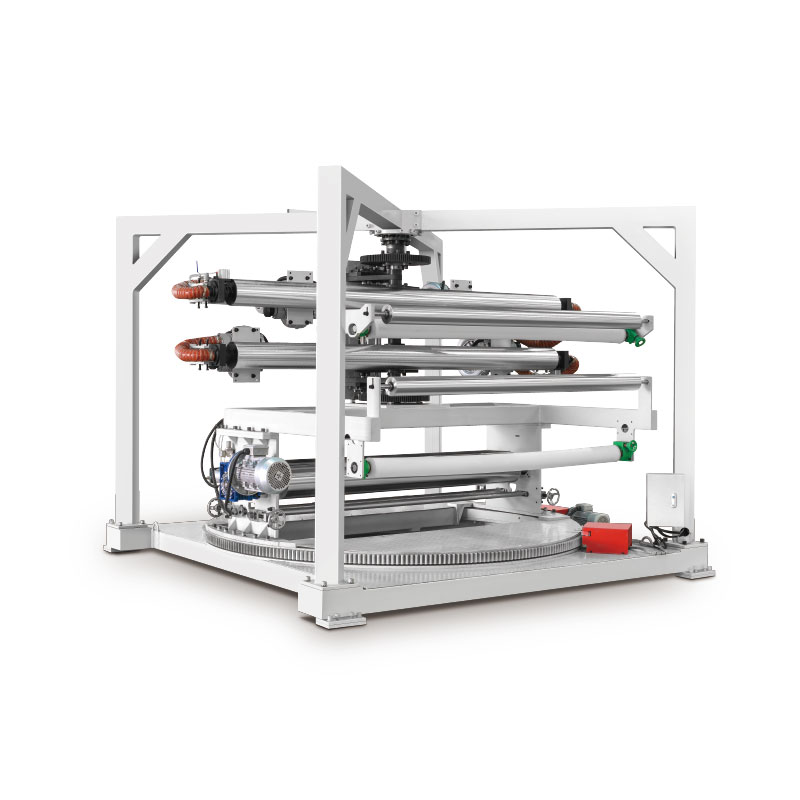

The up-traction determines the Traction stability, plastic film flatness and embossing effect.

The thick frame makes the machine more durable and reliable.

External circulation oil cooling system and hard tooth ensures the high working speed and lifespan of the gear joint.

Advanced heating is much better in terms of life, heating speed and heat preservation effect than stainless steel heating.

The structurally optimized high-speed air ring reduces the wind resistance and make the change of wind volume gentle.

Chaoxin creates a precedent of guarantee period in this industry, which enables clients to get trully hassle-free products & sevice.

5S management standards and high-end machining center equip Chaoxin with precision production capabilities and ensure product standards and quality.