Main motorSiemens(Germany) ,Brook(UK) ,GE(USA)

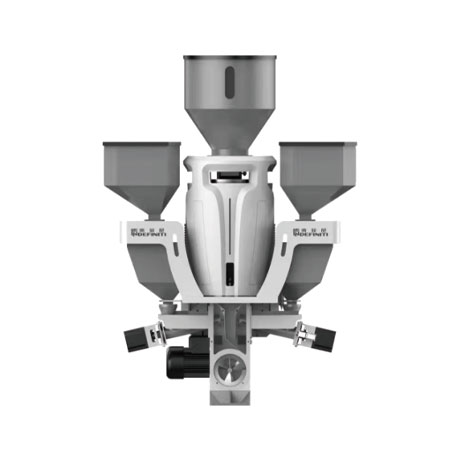

Suitable materialsHDPE/LDPE/LLDPE

Screw L/D30:1

InverterSchneider(French), ABB(Switzerland)

Temperature-controlled meterOmron

Air ringDouble vent air ring

Air blower18kw/23kw/28kw

Winding typeDouble winding

Product Specifications

| MODEL | CX-700 | CX-900 | CX-1100 | |

| Suitable materials | HDPE, LDPE, LLDPE | HDPE, LDPE, LLDPE | HDPE, LDPE, LLDPE | |

| Film width | 100-600mm | 400-800mm | 500-1000mm | |

| Film thickness | 0.006-0.10mm | 0.006-0.10mm | 0.006-0.10mm | |

| Max.extrusion output | HDPE | 60kg | 80kg | 100kg |

| LDPE | 80kg | 100kg | 120kg | |

| Screw diameter | 50mm | 55mm | 60mm | |

| Screw L/D | 32:1/30:1 | 32:1/30:1 | 32:1/30:1 | |

| Gearbox | 146 | 173 | 180 | |

| Main motor | 15kw | 18.5kw | 22kw | |

| Air blower | 3kw | 4kw | 5.5kw | |

| Average power consumption | 18kw | 23kw | 28kw | |

| Die diameter | HDPE | 60mm | 80mm | 100mm |

| LDPE | 120mm | 150mm | 200mm | |

| Traction roller width | 700mm | 900mm | 1100mm | |

| Dimension/Weight | 6*3*5.2m/3.5T | 6*3*5.2m/4T | 6*3.2*6.2m/4.5T | |

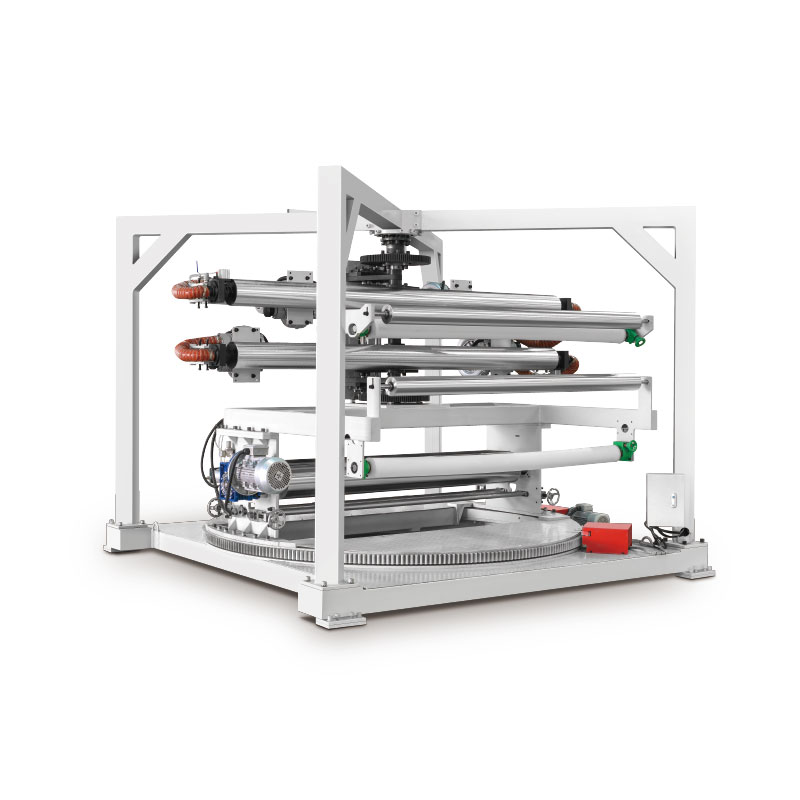

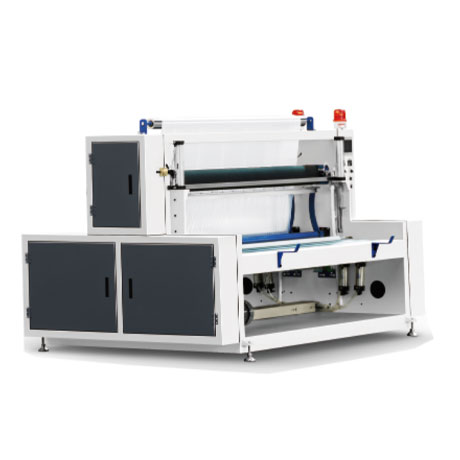

Our single-layer blown film machine provides an excellent solution for common plastic packaging in the market. Compared to ABA blown film machines, single-layer machines are relatively affordable, and they offer a quick return on investment. They can also produce high-quality thin films suitable for packaging various products such as garbage bags, milk tea bags, vest bags, flat bags, and more. The film width can range from 300mm to 1600mm and can be customized according to customer requirements, suitable for HDPE and LDPE films.

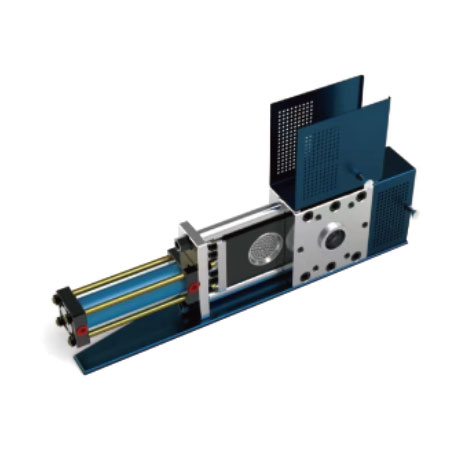

Our machine uses a ceramic heating method for the die head, ensuring even heating of the film. The air ring employs a dual air inlet design based on Italian core technology. We use five rollers for film traction, including one embossing roller, one bending roller, one polyurethane roller (commonly used materials in the market are NBR), and two traction rollers. This differs from other blown film machines on the market, which typically use three traction rollers. For single-layer films, a manual or automatic double winding device can be added for winding.

Depending on production capacity and the customer's factory space and layout, we offer various double winding methods to increase production efficiency

We are excited to introduce our latest product, the single-layer high-speed automatic double-winder film blowing machine, an industry-leading product that combines innovative technology, efficient energy use and versatility.

This film blowing machine uses a double alloy screw and barrel to ensure durability and stability in high-intensity production conditions. Its high-speed screw design (30:1 to 32:1 aspect ratio) makes it excellent in the extrusion process, creating a more uniform film quality. At the same time, our proud dual outlet air ring technology ensures unparalleled uniformity and effect of film cooling.

HDPE, LDPE, LLDPE - Whatever your production needs, our film blowers can easily do the job. Film widths range from 300mm to 1200mm and film thicknesses are adjustable to meet a wide range of packaging and covering applications, giving you greater flexibility in your production.

Four independent temperature control areas of the barrel, with advanced inverters and temperature controllers, ensure precise control of different plastic raw materials and improve product quality and stability. The powerful 30kW main motor provides a solid power base for efficient extrusion, ensuring continuous and stable operation of your production line.

We have the future in mind for you, with an average power consumption of only 18kW, combined with intelligent design, which minimizes energy costs. By choosing our film blowers, you not only get high productivity, but also achieve the goal of green production.

Every customer is unique, so we offer flexible, customized services. Whatever your requirements for film specifications, we will provide you with the best solution. We are committed to being your successful partner.

Buy our film blowers and you will receive a full range of support services. From pre-sales consultation, equipment installation and commissioning, to training and after-sales maintenance, we will always accompany you to ensure that you are always in the best production condition.

Choosing our single-layer high-speed film blowers is a smart choice for innovation, quality and efficiency. We look forward to working with you to open a new era of production excellence. Contact our sales team for more details and discover how to take your production to the next level!

Optimized screw raises the extrusion volume and using lifespan. Higher anti-corrupt and anti-grind ability.

The motor operates with frequency conversion, which shows its advantages in terms of energy saving.

The up-traction determines the Traction stability, plastic film flatness and embossing effect.

The thick frame makes the machine more durable and reliable.

External circulation oil cooling system and hard tooth ensures the high working speed and lifespan of the gear joint.

Advanced heating is much better in terms of life, heating speed and heat preservation effect than stainless steel heating.

The structurally optimized high-speed air ring reduces the wind resistance and make the change of wind volume gentle.

Chaoxin creates a precedent of guarantee period in this industry, which enables clients to get trully hassle-free products & sevice.

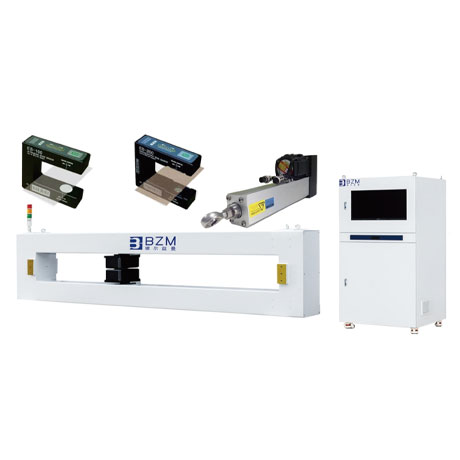

5S management standards and high-end machining center equip Chaoxin with precision production capabilities and ensure product standards and quality.

ZHEJIANG CHAOXIN MACHINERY TECHNOLOGY CO..LTD

Booth No: M460

Time: 2025.03.11(Tue) ~ 2025.03.14(Fri)

Add: KINTEX Exhibition Center 1, Goyang, Korea