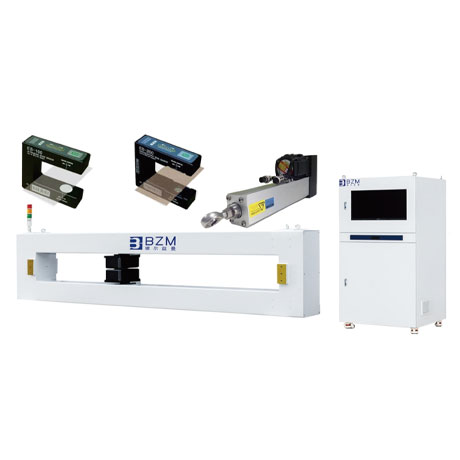

Main motorSiemens(Germany) ,Brook(UK) ,GE(USA)

Suitable materialsLDPE/HDPE/LLDPE

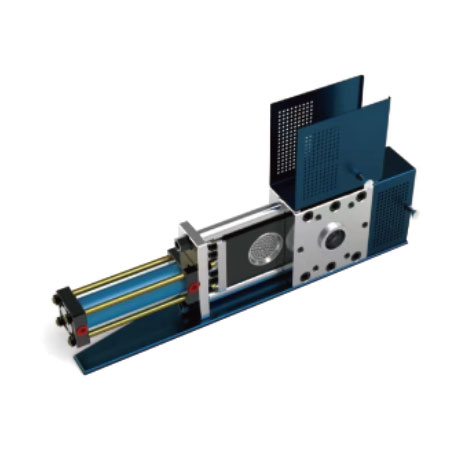

Screw L/D32:1/30:1

InverterSchneider(French), ABB(Switzerland)

Temperature-controlled meterOmron

Air ringDouble vent air ring

Main motor15KW*2/18.5KW*2/18.5KW*2

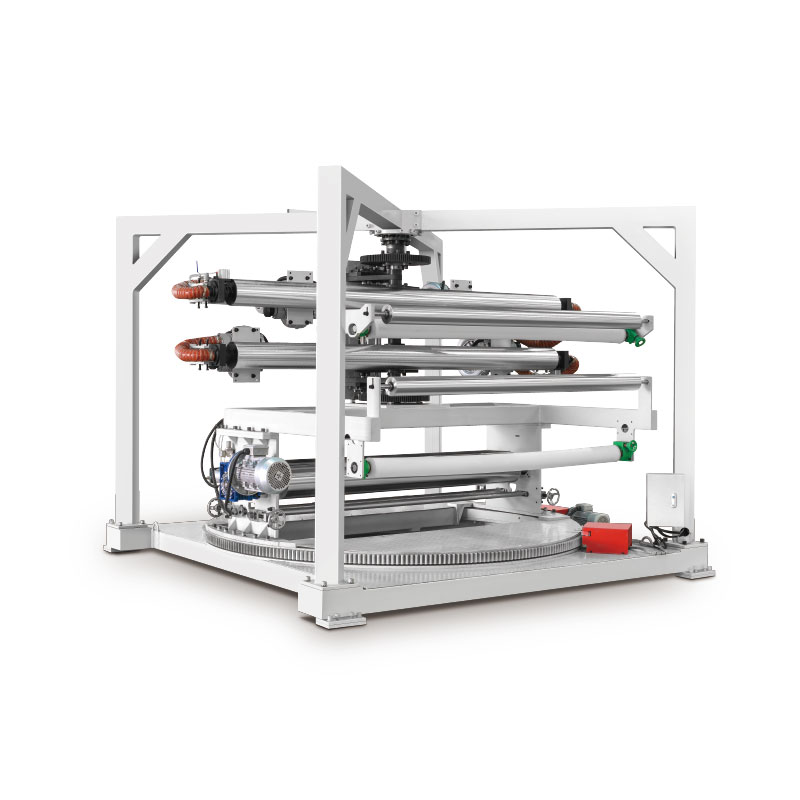

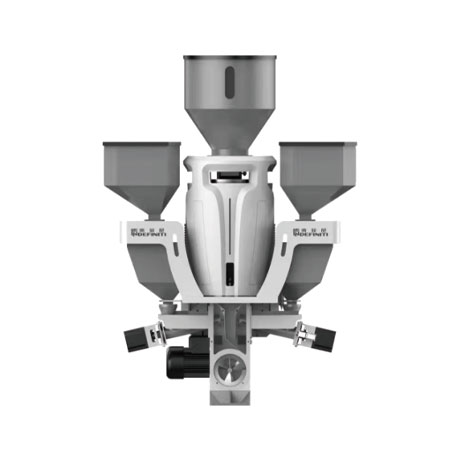

A simple and flexible for producing HDPE/LDPE/LLDPE

Garbage bags. Shrink film.T-shirt bags.

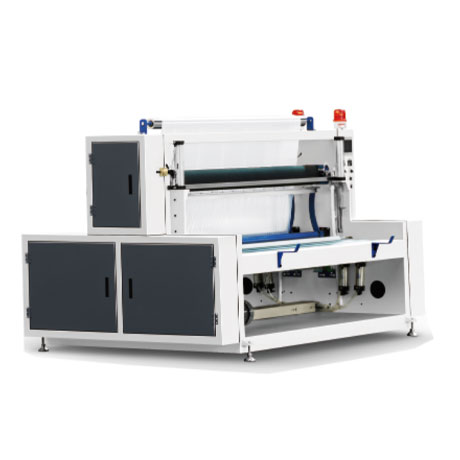

Designed for flexible packaging industry

Product Specifications

characteristics. It is one of the key production equipment in the modern packaging industry, providing reliable solutions for product packaging and protection, and promoting the development and innovation of the industry.

Energy efficient: Reduce costs, save resources while ensuring the stretchability and uniformity of the film

Saving raw materials: Through the design of the ABA structure, recycled materials can be used in the center layer.

A layer material: Generally reinforced materials or functional materials, which give the film more functionality and application advantages.

High production efficiency: Multiple layers of film can be extruded at the same time to improve production efficiency.

Since the current market competition for PE plastic packaging films is very fierce, and the blown film bag making industry is an industry that achieves large-scale market competition based on large-scale production, so production capacity and cost are particularly important.

The three-layer structure of the ABA blown film machine can achieve the same thickness and strength of film with less raw materials, effectively saving raw material costs.

Compared with traditional single-layer film blowing machines, production efficiency and capacity are greatly improved. Compared with the ABC three-layer machine, the ABA blown film machine is also more economical because there is one less extruder.

|

MODEL |

CX-ABA-900 |

CX-ABA-1300 |

CX-ABA-1600 |

CX-ABA-2200 |

|

Suitable materials |

LDPE,LLDPE |

|||

|

Film width |

400-800mm |

600-1200mm |

1000-1500mm |

1500-2050mm |

|

Film thickness |

0.02-0.2mm |

|||

|

Max.Output |

120kh/h |

160kh/h |

180kh/h |

220kh/h |

|

Screw Diameter |

Φ50*2 |

Φ55*2 |

Φ60*1 Φ65*1 |

Φ65*1 Φ75*1 |

|

Screw L/D Lenth |

30:1/32:1 |

|||

|

Cylinder Cooling |

550w*6 |

655w*6 |

550w*7 |

550w*8 |

|

Main Motor |

15kw*2 |

18.5w*2 |

22kw*1 30kw*1 |

30kw*1 37kw*1 |

|

Average Power Consume |

35kw |

45kw |

60kw |

85kw |

|

Air Blower |

5.5kw |

7.5kw |

7.5-11kw |

11kw |

|

Roller Width |

900mm |

1300mm |

1600mm |

2200mm |

|

Effective Width |

800mm |

1200mm |

1500mm |

2050mm |

|

Take-up Speed |

10-120m/min |

|||

|

Power Supply |

380V,50HZ,3PHASE |

|||

|

Outline Dimension(L*W* H) |

6*3*5.8m |

6*3.5*6.5m |

6*4*7.5m |

7*4.5*9.5m |

|

Weight |

3t |

4t |

5.5t |

7.5t |

To enhance the quality of the plastic film and your blown film experiences, all blown film extrusion lines from CHAOXIN allow producers to install add-ons according their needs, including auto loader, rotary die devices, bubble controller, embossing roller, corona treater, hot slitting knife, auto-winder, etc.

We Are A Professional-grade Manufacturer Of Plastic Extrusion Products.

Chaoxin are known for excellent performance based on competitive prices, first class crafts, safe packaging and timely delivery.

We are committed to establish a leading enterprise in producing biodegradable, compostable and plastic film blowing machine, bag

making machine,printing machine etc.

Optimized screw raises the extrusion volume and using lifespan. Higher anti-corrupt and anti-grind ability.

The motor operates with frequency conversion, which shows its advantages in terms of energy saving.

The up-traction determines the Traction stability, plastic film flatness and embossing effect.

The thick frame makes the machine more durable and reliable.

External circulation oil cooling system and hard tooth ensures the high working speed and lifespan of the gear joint.

Advanced heating is much better in terms of life, heating speed and heat preservation effect than stainless steel heating.

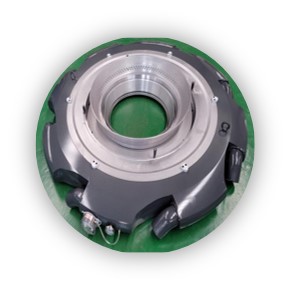

The structurally optimized high-speed air ring reduces the wind resistance and make the change of wind volume gentle.

Chaoxin creates a precedent of guarantee period in this industry, which enables clients to get trully hassle-free products & sevice.

5S management standards and high-end machining center equip Chaoxin with precision production capabilities and ensure product standards and quality.

ZHEJIANG CHAOXIN MACHINERY TECHNOLOGY CO..LTD

Booth No: 1K11

Time: 2025. 4. 15 - 18

Add: Shenzhen World Exhibition & Convention Center (Bao'an), PR China