The traction ratio refers to the ratio between the film traction speed and the tube ring extrusion speed. The traction ratio is the longitudinal stretching multiple, which makes the film oriented in the drawing direction. As the traction ratio increases, the longitudinal strength will also increase, and the thickness of the film will become thinner. However, if the traction ratio is too large, the thickness of the film will be difficult to control, and the film may even be pulled apart, causing film breakage. The traction ratio of low-density polyethylene (LDPE) film is generally controlled between 4 and 6.

The blow-up ratio is one of the key control points in the production process of blown film. It refers to the ratio between the diameter of the film bubble after blowing and the diameter of the tube ring before blowing. The blow-up ratio is the transverse expansion multiple of the film. In fact, the film is stretched transversely. Stretching will have a certain degree of orientation effect on the plastic molecules. The increase of the blow-up ratio will increase the transverse strength of the film. However, the blow-up ratio cannot be too large, otherwise it will easily cause the film bubble to be unstable and the film will easily wrinkle. Therefore, the blow-up ratio should be properly matched with the traction ratio. Generally speaking, the blow-up ratio of low-density polyethylene (LDPE) film should be controlled at 2.5~3.0.

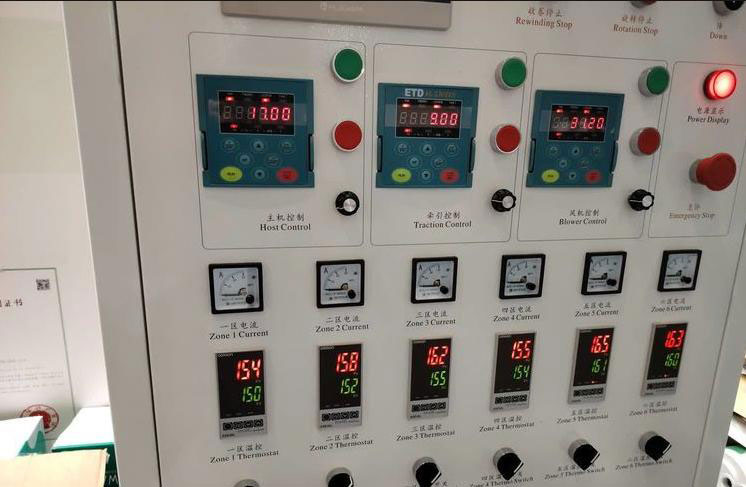

When blowing low-density polyethylene (LDPE) film, the extrusion temperature is generally controlled between 160°C and 170°C, and the temperature of the machine head must be ensured to be uniform. If the extrusion temperature is too high, the resin will easily decompose and the film will become brittle, especially The longitudinal tensile strength is significantly reduced; if the temperature is too low, the resin will be poorly plasticized and cannot expand and stretch smoothly. The tensile strength of the film is low, and the surface gloss and transparency are poor, and even appear like wood growth rings. Similar patterns and unmelted crystal nuclei.

The raw materials used should be blown film grade polyethylene resin particles, containing an appropriate amount of lubricant to ensure the opening of the film.

The melt index (MI) of the resin particles should not be too large. If the melt index (MI) is too large, the viscosity of the molten resin will be too small, the processing range will be narrow, the processing conditions will be difficult to control, the film-forming property of the resin will be poor, and it will not be easy to process into a film; in addition, if the melt index (MI) is too large, the relative molecular weight distribution of the polymer will be too narrow, and the strength of the film will be poor. Therefore, a resin raw material with a small melt index (MI) and a wide relative molecular weight distribution should be selected, which can not only meet the performance requirements of the film, but also ensure the processing characteristics of the resin. Blown polyethylene film generally uses polyethylene raw materials with a melt index (MI) in the range of 2~6g/10min.

Blown film is a tubular film product obtained by extruding plastic into a thin tube, then blowing the plastic with compressed air while it is hot, and then cooling and shaping it. The performance of this film is between oriented film and cast film: the strength is better than cast film, and the heat sealing property is worse than cast film. There are many types of films produced by the blow molding method, such as low-density polyethylene (LDPE), polypropylene (PP), high-density polyethylene (HDPE), nylon (PA), ethylene-vinyl acetate copolymer (EVA), etc. Here we briefly introduce the blow molding production process of commonly used low-density polyethylene (LDPE) film and its common faults.