In Malaysia's plastic packaging industry belt, a company that has been deeply engaged in the production of low-pressure fresh-keeping bags is facing the pain of transformation: the low automation, high energy consumption and limited plant space of traditional equipment have become stumbling blocks for its market expansion. An accidental search on Alibaba International Station led them to meet Zhejiang Chaoxin Machinery Technology Co., Ltd., and started an upgrade journey from "manufacturing" to "intelligent manufacturing.

Low Automation & Efficiency: Manual operations led to inefficiency and yield fluctuations.

Space & Equipment Constraints: Large, outdated equipment restricted factory layout and production capacity.

Need for Upgrade: Customer sought compact, intelligent, and cost-effective equipment to improve operations.

Customer pain point: traditional equipment drags down development

The customer is a large-scale fresh-keeping bag manufacturer in Malaysia, mainly producing LDPE fresh-keeping bags with specifications of 50-300mm. Although the product quality is stable, the core problems of the existing equipment are:

1. Relying on manual operation, production efficiency is limited, and it is easy to cause fluctuations in yield due to human errors.

2. The old equipment is large in size and the factory layout is crowded, which restricts the expansion of production capacity.

3. The smooth roll-changing design causes frequent slipping during rewinding, resulting in material waste and downtime losses.

In order to break through the bottleneck, the customer urgently needs a film blowing equipment with high cost performance, small footprint and high degree of intelligence.

After in-depth research, Rena, the regional manager of Chaoxin Machinery, accurately matched the low-pressure 1100 single-machine semi-automatic winding Film Extrusion Machine for the customer and innovatively proposed an upgrade plan:

1. The semi-automatic winding system reduces manual intervention, improves efficiency by 30%, and reduces the operating threshold.

2. The compact modular design has a body size that is 25% smaller than traditional models, which is suitable for crowded factories and releases storage space.

3. The friction roll-changing technology completely solves the slipping problem through a patented friction drive device, and the material loss rate is reduced by 15%.

4. One Film Extrusion Machine has multiple uses, supports free switching of 50-1100mm width, and covers the needs of customers' full product lines.

5. Energy saving and consumption reduction, equipped with an intelligent temperature control system, energy consumption is reduced by 20% compared with traditional equipment.

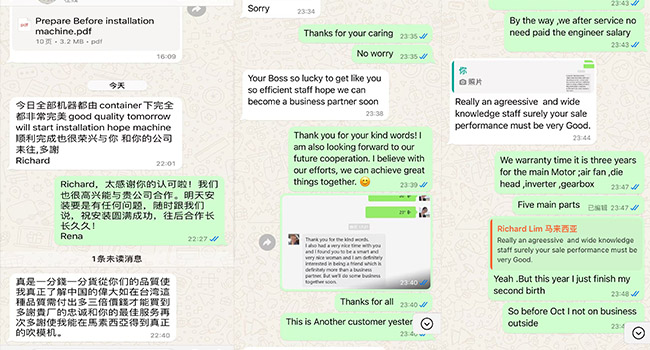

Facing customers' doubts about the new equipment, Rena's team won trust through actions

Scenario-based demonstration, through 3D simulation animation, intuitively shows the actual operation effect of the equipment in the customer's factory, including High Speed Monolayer (Single layer) Film Extrusion Machine space occupancy and operation process.

* Data commitment, providing upgrade data of similar customers in Southeast Asia, and promising to recover the equipment investment cost within 6 months.

* Value-added service, free energy efficiency diagnosis for customers' existing equipment, and free friction winding technology upgrade plan.

"Rena's solution is not a simple equipment replacement, but an optimization of the entire production process." The customer manager said, "Especially the friction roll changing technology, which directly solved our long-term headache quality problem."

After the equipment was put into operation, the customer's gains exceeded expectations:

1. The daily output of a single device increased from 5 tons to 7 tons, and the yield rate was stabilized at more than 98%.

2. Labor costs decreased by 40%, material waste decreased by 15%, and ROI was achieved within half a year.

3. The new equipment occupies a 25% smaller area, and the freed space is used to add a storage area, which greatly enhances the order acceptance capacity.

"Chaoxin Film Extrusion Machine not only provides cost-effective equipment, but also allows us to see the unlimited possibilities of technology upgrades through professional services."

— Production Director, Malaysian Client

ZHEJIANG CHAOXIN MACHINERY TECHNOLOGY CO..LTD

Booth No: GH189

Time: March 24-28, 2025

Add: SÃO PAULO EXPO – EXHIBITION & CONVENTION CENTER