In Ethiopia’s plastics processing industry, Zhejiang Chaoxin Machinery Technology Co., Ltd. has earned a stellar reputation for its reliable and high-efficiency equipment. A local client, after visiting multiple factories and discovering Chaoxin’s HDPE/LDPE Blown Film Extruder Machines in operation, embarked on a cross-border collaboration that bridged geographical and technological boundaries.

Client’s Challenge: Existing machinery was inefficient with high energy consumption and limited film width.

Discovery of Chaoxin: The client found Chaoxin Machinery through a Google search based on equipment details.

Successful Partnership: Chaoxin's advanced machinery improved production efficiency and competitiveness in Ethiopia.

Specializing in 400-500mm wide shrink films, the client faced limitations with their existing machinery—maximum 600mm film width, high energy consumption, and low efficiency. To enhance competitiveness, they evaluated seven to eight domestic Double Winding HDPE/LDPE Blown Film Extruder Machine manufacturers but found no ideal solution. The breakthrough came when the client identified Chaoxin Machinery through a Google search based on equipment nameplate information, initiating a transformative partnership.

Chaoxin’s technical team prioritized problem-solving over salesmanship, conducting an in-depth analysis of the client’s production needs and long-term goals:

1. Precision Diagnosis: Identified severe material waste and excessive energy costs due to outdated equipment constraints.

2. Tailored Solution: Recommended Chaoxin’s 1100mm modular blown film machine, which allows adjustable film widths from 400mm to 1100mm, fully addressing the client’s demand for 400-500mm films.

3. Performance Leap: Equipped with an intelligent temperature control system and energy-saving motors, the Double Winding HDPE/LDPE Blown Film Extruder Machine tripled output while reducing energy consumption by 25%, meeting diversified demands for shrink films.

To alleviate initial concerns, Chaoxin implemented a confidence-building strategy:

1. Shared operational data from Southeast Asian clients, including energy consumption curves, ≥98% yield rates, and maintenance cycles.

2. Offered free energy audits for existing production lines and dispatched engineers for on-site commissioning to ensure seamless integration.

3. Provided a 3-year warranty and 24/7 remote technical support.

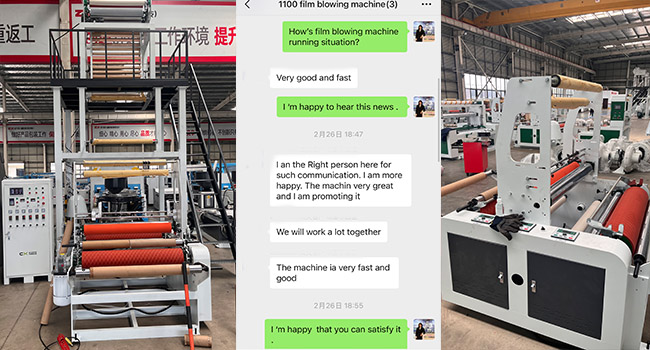

Post-installation results surpassed expectations:

* Daily output per machine soared from 3 tons to 9 tons, enabling large-order fulfillment and market expansion.

* Reduced energy costs translated to rapid ROI, with equipment investment recouped within 6 months.

* Chaoxin’s training empowered the client to shrink film techniques, transitioning to high-value-added products.

Client Testimonial:

Chaoxin Double Winding HDPE/LDPE Blown Film Extruder Machine made the impossible possible. While other suppliers offered generic solutions, their team truly understood our needs. They not only delivered cost-effective equipment but also redesigned our entire production workflow. Our capacity and profits have multiplied, thanks to Chaoxin's expertise!

— Production Director, Ethiopian Client

CONTACT: Shally hong

PHONE:+8615067801066

EMAlL :Sales6@zjchaoxin.com

ZHEJIANG CHAOXIN MACHINERY TECHNOLOGY CO..LTD

Booth No: 1K11

Time: 2025. 4. 15 - 18

Add: Shenzhen World Exhibition & Convention Center (Bao'an), PR China